- Koldpack and the iRobolution team developed a future-generation mechanism into the robotics sector that eliminates a big space for the drum filling system. Non-metallic nozzle lance have been invented for the 1st time in India to ensure uninterrupted operations.

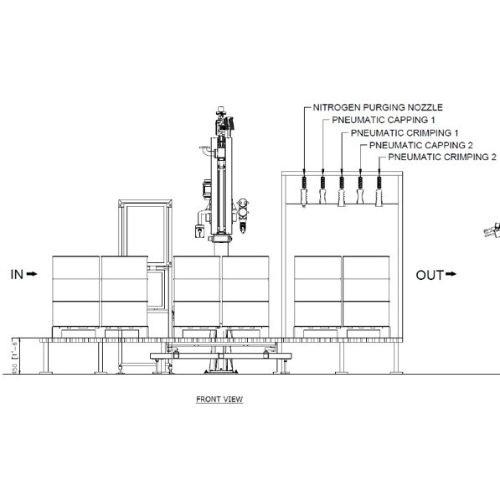

- Inspiration's main objective is to fill pallets. Following that, other features were added to increase capacity, such as pneumatically powered on-hand controls for bung alignment, lance movement, in-feed and out-feed motorized conveyors, capping, crimping, and so on.

- All batch operations data may be accessed with a single touch for batch monitoring, optimization, and standardized operations, thanks to programming and integration with DCS.

Semi-Auto Drum on Pallet Filling Machine

- Non-Metallic Filling Nozzle Lance (for anti-corrosive and long-lasting smooth operation).

- Fume Hood SS-304 (to ensure safe work place).

- On Hand Controls for Start and Emergency Stop Buttons,

- Non-Metallic Drip Cup (with auto-displacement),

- Spring Balancer (to eliminate hose weight during lance movement).

- Individual PLC, Controller and Flameproof enclosure instead of Controller based Sov Box Clean in Place with Single Touch Button from Touch HMI (to eliminate down-time and Dismantle process),

- Fail Safe Provisions (to avoid any Unanticipated event).

- Smart Algorithms Based System,Smart Algorithms Based System,

- Bung Align Detection, Warning Alarms for Variations in Flow Rate.

- Most Important Remote Module for Service Support (to diagnose and calibrate through internet).

- Industry Use: Food Oil, Grease oil, Paint, Lubricants, Chemical, Pharma API, Adhesive, etc.

Semi-Auto Drum Filling with Pallet Conveyor

- Non-Metallic Filling Nozzle Lance (for anti-corrosive and long-lasting smooth operation).

- Fume Hood SS-304 (to ensure safe work place).

- On Hand Controls for Start and Emergency Stop Buttons,

- Non-Metallic Drip Cup (with auto-displacement),

- Spring Balancer (to eliminate hose weight during lance movement).

- Individual PLC, Controller and Flameproof enclosure instead of Controller based Sov Box Clean in Place with Single Touch Button from Touch HMI (to eliminate down-time and Dismantle process),

- Fail Safe Provisions (to avoid any Unanticipated event).

- Smart Algorithms Based System,Smart Algorithms Based System,

- Bung Align Detection, Warning Alarms for Variations in Flow Rate.

- Most Important Remote Module for Service Support (to diagnose and calibrate through internet).

- Industry Use: Food Oil, Grease oil, Paint, Lubricants, Chemical, Pharma API, Adhesive, etc.