Brief Introduction

Orange & citrus fruits originated in southern asia & spread gradually. To have in a citrus fruit & orange processing we are leading supplier in asia as well as globally. Reliable, high-yield citrus extractors, juicers, and finishers — creating exceptional-quality products — for profit- and sustainability-minded processors.

For you this means we know how to make transforming oranges, lemons, limes, and all their kin into tasty, refreshing products. Plus, we’ve got all the citrus processing equipment you’ll need – from start to finish – for smooth operations, cost effective production, and the highest-quality juices, pulps, purees and more.

For you this means we know how to make transforming oranges, lemons, limes, and all their kin into tasty, refreshing products. Plus, we’ve got all the citrus processing equipment you’ll need – from start to finish – for smooth operations, cost effective production, and the highest-quality juices, pulps, purees and more.

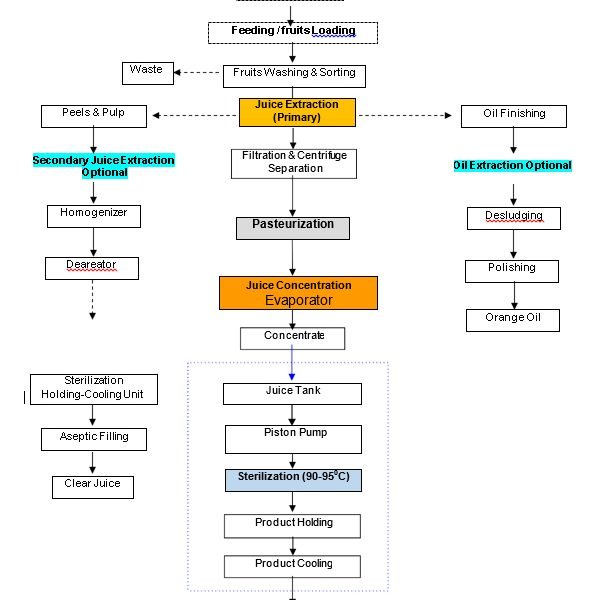

While our Citrus Extractor is the celebrity at the center of any citrus processing system, Koldpack has solutions for:

- Fruit storage, receiving and handling

- Juice room equipment

- Citrus pulp processing

- Not-from-concentrate production

- Frozen concentrated juice production

- Peel/waste processing

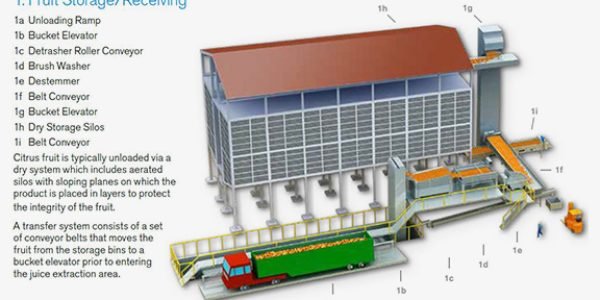

Fruit storage receiving & handling

The fruit storage & receiving section is used to handle & clean raw fruits which include below processes: Fruit unloading

- Transfer system & brush washing

- Fruit grading & sizing

- Fruit feeding

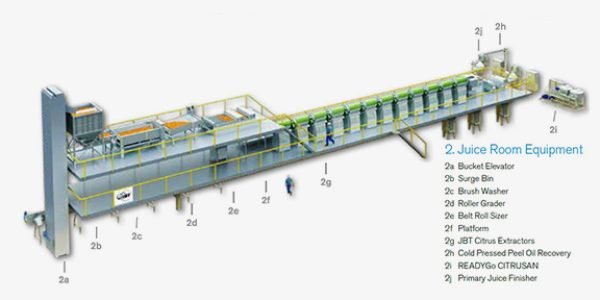

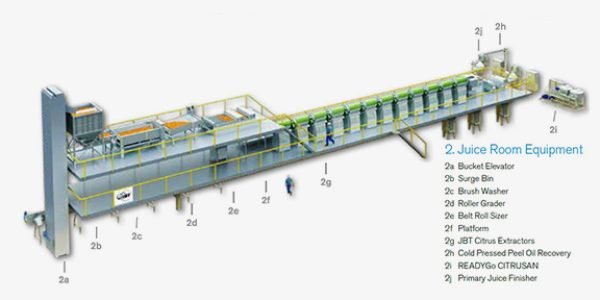

Citrus juice extraction unit

Fruit delivered from the tilted feed belt conveyor is fed into the extraction cups singly. Fruit drops into a stationary lower cup which automatically centers and positions it for extraction. AS the fruit is pressed into the strainer tube where the juice and juice cells are instantaneously separated from the seeds and section membrane. As a result, only pure juice and juice cells are discharged into the juice manifold.

Fruit delivered from the tilted feed belt conveyor is fed into the extraction cups singly. Fruit drops into a stationary lower cup which automatically centers and positions it for extraction. AS the fruit is pressed into the strainer tube where the juice and juice cells are instantaneously separated from the seeds and section membrane. As a result, only pure juice and juice cells are discharged into the juice manifold.

Citrus juice extraction unit

Finishing & evaporation

Fishing is process of efficiently removing pulp and/or juice sacs from the juice by using stainless steel screens with small perforations.

After fishing the product is thermally accelerated evaporates for a short time to maintain fresh aroma of juice.

After fishing the product is thermally accelerated evaporates for a short time to maintain fresh aroma of juice.

Juice cooling & aseptic filling

The concentrated juice leaving the evaporator is delivered to a standardizing and refrigerating system prior to filling. In the heat exchanger the juice is cooled down to a very low temperature by means of glycol water supplied by a chilling unit.

After that the concentrated juice is accurately and reliably filled into drums by means of a fully automatic or semi-automatic controlled system with preset weight scales.

After that the concentrated juice is accurately and reliably filled into drums by means of a fully automatic or semi-automatic controlled system with preset weight scales.

The concentrated juice leaving the evaporator is delivered to a standardizing and refrigerating system prior to filling. In the heat exchanger the juice is cooled down to a very low temperature by means of glycol water supplied by a chilling unit.

After that the concentrated juice is accurately and reliably filled into drums by means of a fully automatic or semi-automatic controlled system with preset weight scales.

After that the concentrated juice is accurately and reliably filled into drums by means of a fully automatic or semi-automatic controlled system with preset weight scales.

Juice cooling & aseptic filling

Peel collection & process

A special system of screw conveyors takes the citrus peel as well as waste pulp and membrane material to a dedicated silo tank.

to reduce peel moisture content from the initial 82% to a final 8% specially designed peel drying system, is used.

to reduce peel moisture content from the initial 82% to a final 8% specially designed peel drying system, is used.

Peel evaporation & filling

The air vapor mixture coming from the peel drier is separated from the powders then conveyed.

READY Go™ “COMPACT” mono blocks are available with capacities ranging from 500 to 6000 kg/h. They are designed for the aseptic filling of 5 to 200 liter bags and can process the following products: fruit purees with or without pieces, concentrated fruit purees, and many other formulated products.

READY Go™ “COMPACT” mono blocks are available with capacities ranging from 500 to 6000 kg/h. They are designed for the aseptic filling of 5 to 200 liter bags and can process the following products: fruit purees with or without pieces, concentrated fruit purees, and many other formulated products.

The air vapor mixture coming from the peel drier is separated from the powders then conveyed.

READY Go™ “COMPACT” mono blocks are available with capacities ranging from 500 to 6000 kg/h. They are designed for the aseptic filling of 5 to 200 liter bags and can process the following products: fruit purees with or without pieces, concentrated fruit purees, and many other formulated products.

READY Go™ “COMPACT” mono blocks are available with capacities ranging from 500 to 6000 kg/h. They are designed for the aseptic filling of 5 to 200 liter bags and can process the following products: fruit purees with or without pieces, concentrated fruit purees, and many other formulated products.

Peel evaporation & filling