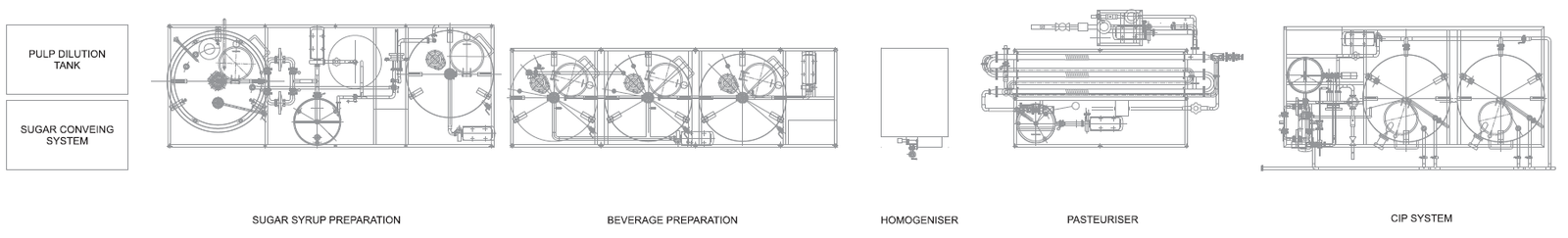

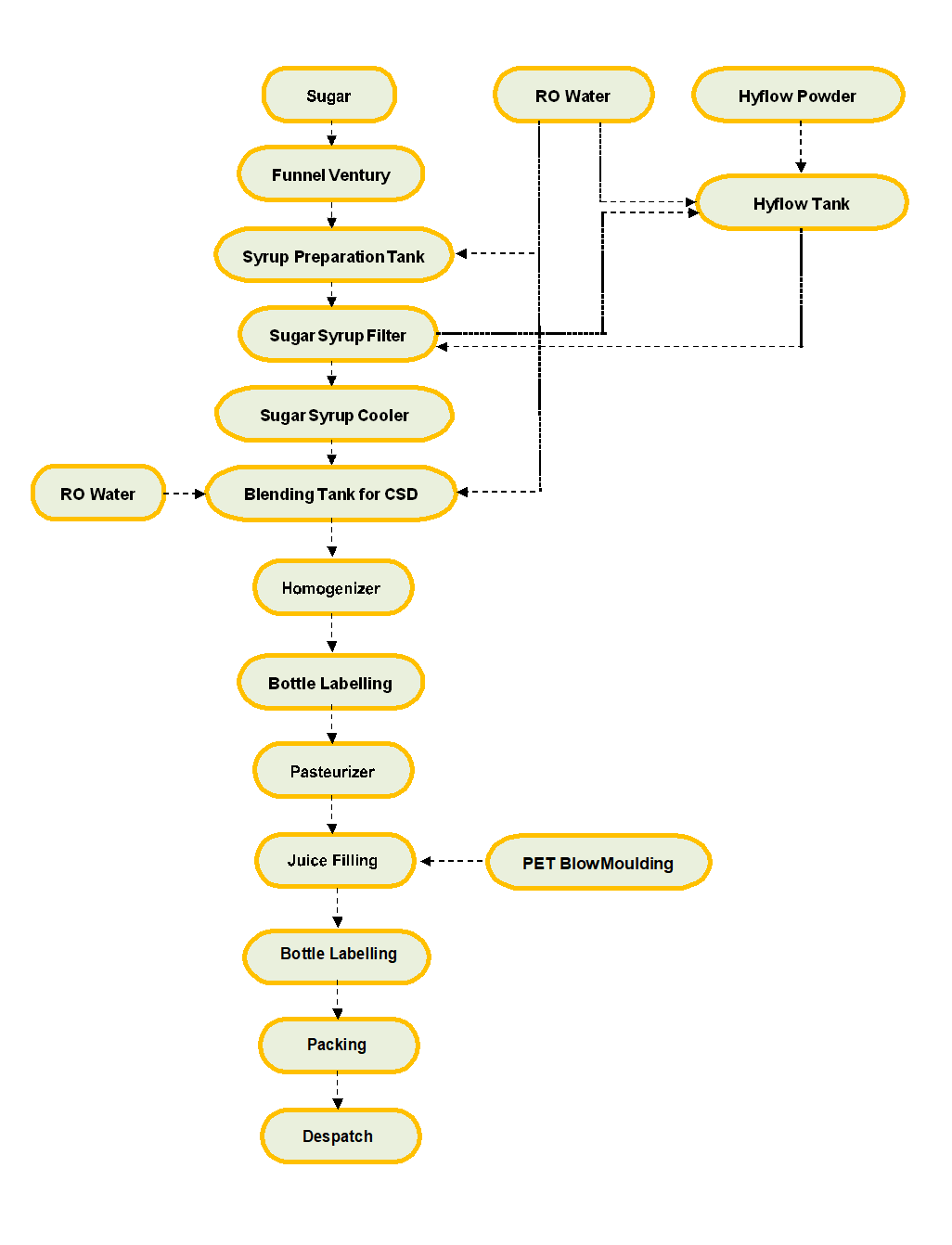

SUGAR SYRUP PREPARATION SECTION

In this section the Equipment are provided to prepare the sugar syrup. Sugar syrup of 65 Brix will be prepared by dissolving the sugar in heated water. After the Sugar syrup is prepared it is passed through filter & then cooled down before transferring it into the Ready Sugar syrup storage tank. From the ready Sugar Syrup storage tank the Syrup would be transferred to the Blending tanks as require.

Bag in Barrel/ Cans or Pulp processing unit are the three ways to get Pulp into the Ready to serve processing unit. This pulp will be dump in hopper from where it will transferred to blending section.

PULP UNLOADING SECTION

BEVERAGE BLENDING SECTION

In this section the Beverage will be Blend by addition of RO water, sugar Syrup, Fruit pulp, additives etc. The Beverage blend will be stirred and then, homogenized and stored in Homogenized Juice storage tank. From the Homogenized storage tank the product will be passed through sterilizes for warm Fill which can be connected to the PET Bottle filling Machine.

Ready beverage with pulp is turbid & liquid solid mixture which need to convert into fine, uniform & stable texture of juice which is to be done by homogenization process.

HIGH PRESSURE HOMOGENIZER

SKID MOUNTED TUBULAR PASTURIZER (AUTOMATIC PLC BASED)

Before filling the product external biological agents/bacteria/fungi should be eliminated which may have entered or been present in the product in the process will be eliminated by pasteurizing/sterilizing through plate/tubular/spiral flow/scrapped surface type heat exchangers which is designed for HOT Filling in PET bottle and pasteurizing fruit based beverages and holding for 45 sec. and then sent it to the filling section.

In this section the Beverage will be Blend by addition of RO water, sugar Syrup, Fruit pulp, additives etc. The Beverage blend will be stirred and then, homogenized and stored in Homogenized Juice storage tank. From the Homogenized storage tank the product will be passed through sterilizes for warm Fill which can be connected to the PET Bottle filling Machine.

BEVERAGE BLENDING SECTION

AUTOMATIC CIP SYSTEM

This will be automatic in nature means following action will be taken automatically and some operations will have to be done manually

- The temperature of CIP solution heating will be automatically controlled

- The water level of tank will be maintained automatically

- The opening of respective tank valve has to be done manually for supply as well return

- Flow diversion of liquid to respective tank will be automatic

- But as long as the temperature is not achieved the recirculation valve should be in open condition

The operation timer will cut of the pump as soon the set timing of operation is achieved.