Bottle Unscrambler

Bottle unscrambler is linear type of unscrambling machine, designed for feeding oriented bottles into the production line. It is the perfect labour-saving equipment, no longer is employees required to manually sort bottles and stand them upright on a conveyor. They are suitable for large various of bottle shapes and size. Koldpack bottle unscramble operates with great simplicity, efficiency and minimal maintenance.

If you have demands for a bottle unscramble, our products can certainly live up to your expectations. Welcome to contact Koldpack for more details.

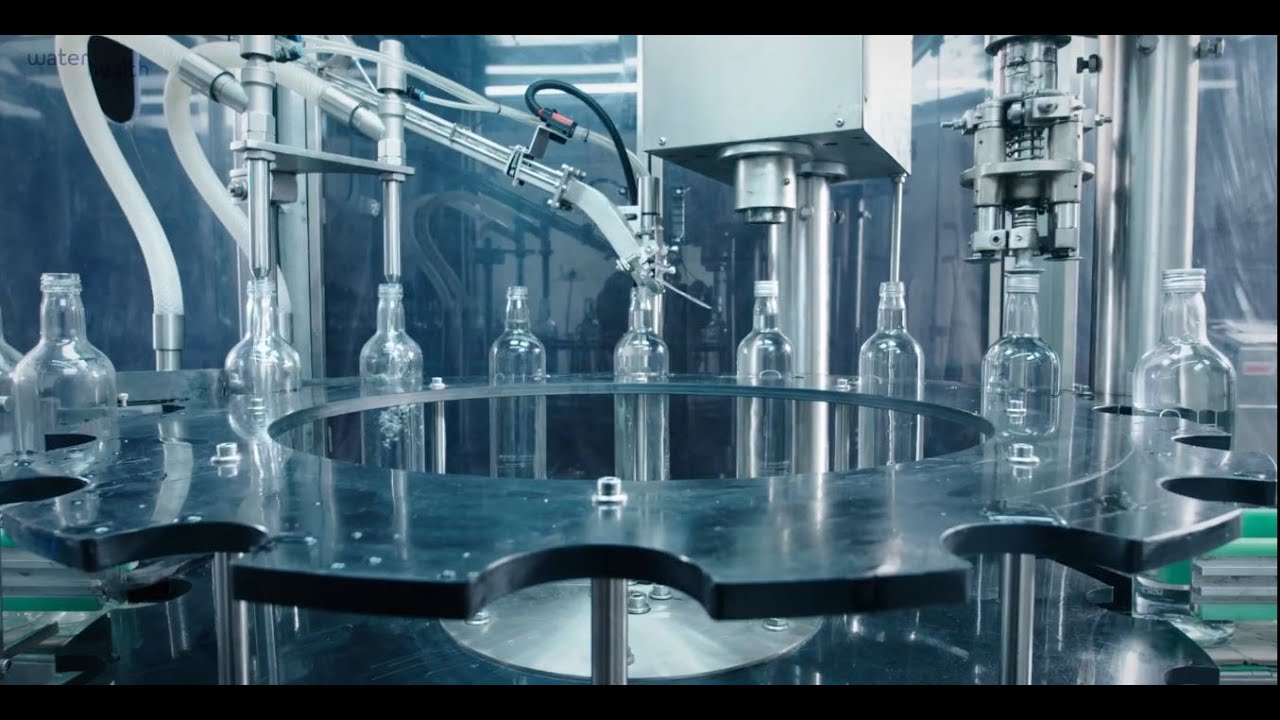

Working:

Bottle are loaded into the hopper, and supplied to the centrifugal disc through an elevator. In the disc, bottles are directed into the orientation area.

Bottles are delivered one by one, and the Bottle Orientating Hook grabs the neck of the bottles for correcting position.

After that, the upright bottles are stabilized and released on the bottle exit conveyor. The Koldpack bottle unscrambler is designed to handle a wide range of plastic bottles. All mechanical adjustments are equipped with numeric counter for easy and repeatable changes.

Features:

- Capable of handling cylinders, squares and rectangles.

- PLC controlled with touch screen panel, easy access to all settings.

- Fast and easy format changes.

- Stainless steel and plastic for bottle contacts.

- Operational simplicity – no specialized personnel needed

- Capacity based on filling line.

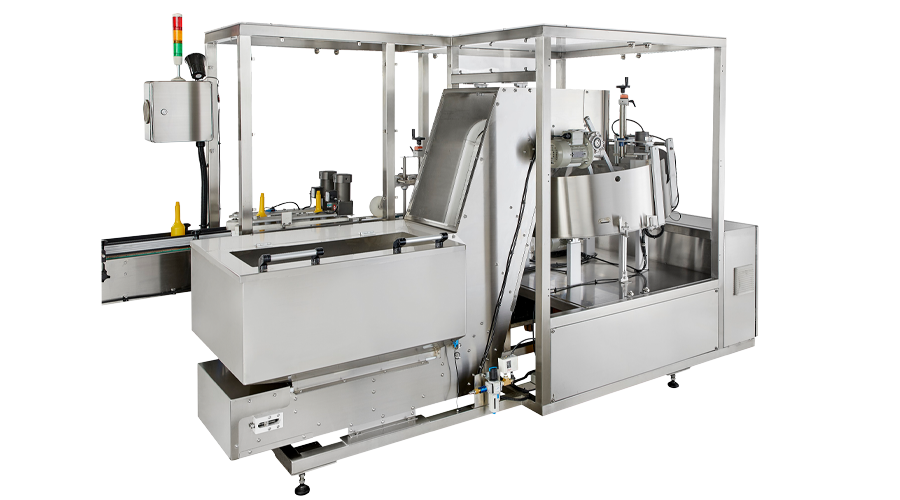

Robotic Unscrambler

iR-unscrambler is a Robotics system to reorient plastic bottles in vertical format after washing or any process before we feed it to an inline filling system. The system design depends on bottle shape, size, speed and base stability & complexity. Right robot selection from SCARA, Articulated six axis robotor delta picker type is a unique capability of iRobolution. System design will play a very important role for right solution at best cost.

Thanks to ViPoCo Technology software and iGripp design for gripping system to manage all versatile bottles.

Thanks to ViPoCo Technology software and iGripp design for gripping system to manage all versatile bottles.

Why iR-unscrambler:

- Unique design position and right robot selection

- Specific Vision software design for the solution

- Gripper technology to handle single as well as multiple bottles

- Small footprint

- Almost negligible change in parts

- Advance control system to give you all alarms and warring massages

iR-unscrambler includes:

- Customized well know Robot brands for handling

- Custom-built robot’s gripper (Innovative gripper designed to handle various sizes of bottles) thanks to iGripp Technology Design

- Right hopper and conveyor for bottle separation

- Air conveyor or Puck type conveyor

- Control system with Industry 4.0 ready

Application:

- Pharma, Personal care, Home care, pesticides bottles handling

- No scratching or rubbing