iRoboFILL (Robotic Drum Filling Machine, Barrel Filling Machine)

- Elevate your industry’s standard with the only Al based robotic barrel filling system. iRobolution and Koldpack team is breaking their own records one after another.

- Customized with the multi-lances, a motorized conveyor, pallet de-stacker and so on with subsequent tasks.

- Most importantly, several possibilities for software development. “Never Settle for Ordinary Products”.

- On pallet filling is the key advantage of iRoboFill drum Filling machine.

iRoboFILL (drum filling machine, barrel filling machine)

- AI based Next-Gen mechanism with upgradation compatibilities.

- Movable nozzle lance to detect the bungs automatically.

- Capping, Crimping and Labelling process managed by same operator.

- Compact and less-complex system provides long-last smooth operation, saves time, unnecessary down-time and maintenance cost.

- Single console to operate and extract the data.

- Filling station becomes an asset.

- Inner-outer lance auto Clean In Place available with single touch.

- Req. 1 operator and fork-lift or trolley handler.

- Easy to relocate and use.

- High accuracy, repeatability and reliability.

- No reservations required for High no. of qty. spares.

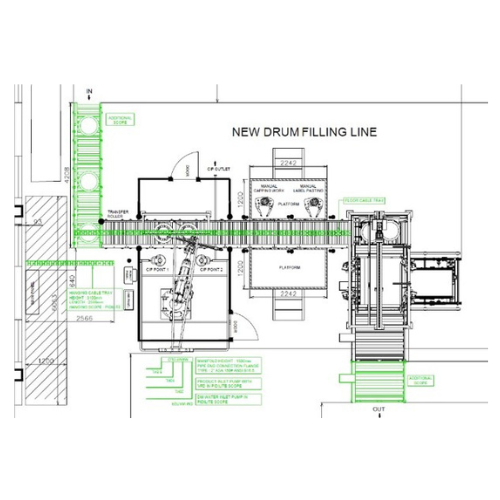

iRoboFill Fully Auto 50, 100, 150, 180, 200, 210, 220, 235 & 250KG Linear-Conveyor Line

- Two drums at a time feeding on conveyor.

- AI based Next-Gen mechanism with upgradation compatibilities.

- Movable nozzle lance to auto-detect the bungs.

- Capping, Crimping and Labelling process managed by semi-auto and fully-auto options.

- Powered with In-feed, Filling and Out-feed conveyor.

- Load-cell technology based filling.

- Can be equipped with Flow Meter based filling.

- Various options for drum palletization.

- Single console to operate and extract the data.

- Filling station becomes an asset.

- Inner-outer lance auto Clean In Place available with single touch.