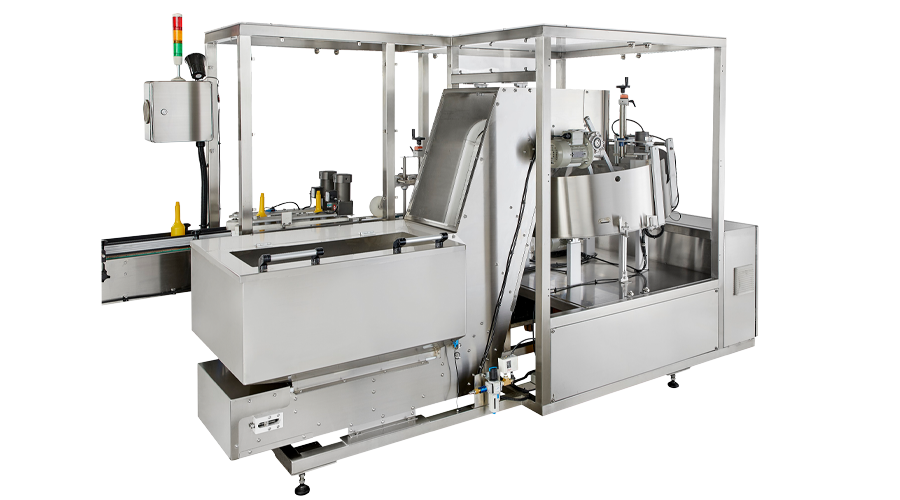

Bottle Unscrambler

A Bottle Unscrambler is a linear machine designed to feed oriented bottles into the production line efficiently. This equipment is ideal for saving labor, eliminating the need for employees to manually sort and stand bottles upright on a conveyor. It handles various bottle shapes and sizes with ease. The Koldpack Bottle Unscrambler operates simply, efficiently, and with minimal maintenance. If you need a reliable bottle unscrambler, our products will meet your needs. Contact Koldpack for more information.

Working:

Bottles are loaded into a hopper and then transported to a centrifugal disc via an elevator. Inside the disc, bottles move to the orientation area. The Bottle Orientating Hook grabs each bottle's neck to correct its position. After this, the bottles are stabilized and placed onto the exit conveyor. The Koldpack Bottle Unscrambler is versatile, handling a wide range of plastic bottles. Mechanical adjustments feature numeric counters for easy and repeatable changes.

Features:

- Handles cylinders, squares, and rectangular bottles.

- PLC-controlled with a touch screen panel for easy access to settings.

- Allows fast and simple format changes.

- Constructed from stainless steel and plastic for bottle contact.

- Operates simply—no specialized personnel required.

- Capacity varies based on the filling line.

Robotic Unscrambler

The iR-unscrambler is a robotic system that reorients plastic bottles into a vertical format after washing or other processes, preparing them for the inline filling system. The design of the system considers factors such as bottle shape, size, speed, base stability, and complexity. iRobolution offers a range of robots, including SCARA, articulated six-axis, and delta pickers, to provide the best solution at the most cost-effective price.

Why iR-unscrambler:

- Features unique design and optimal robot selection.

- Utilizes specific Vision software tailored to the solution.

- Advanced gripper technology handles both single and multiple bottles.

- Compact footprint.

- Requires minimal part changes.

- Equipped with an advanced control system that provides alarms and warning messages.

iR-unscrambler includes:

- Custom-built robots from well-known brands.

- Innovative gripper design (iGripp Technology) for various bottle sizes.

- Appropriate hopper and conveyor for bottle separation.

- Options for air conveyor or puck-type conveyor.

- Control system compatible with Industry 4.0.

Application:

- Ideal for handling bottles in pharma, personal care, home care, and pesticide industries.

- Designed to prevent scratching or rubbing.

Product Category

Primary packaging

– Rinsing for Mineral Water

– Filling for Mineral Water

– Capping for Mineral Water

– Rinsing For Juice

– Hot-Filling For Juice

– Capping For Juice

– Rinsing for Carbonated Soft Drinks

– Filling for Carbonated Soft Drinks

– Capping for Carbonated Soft Drinks

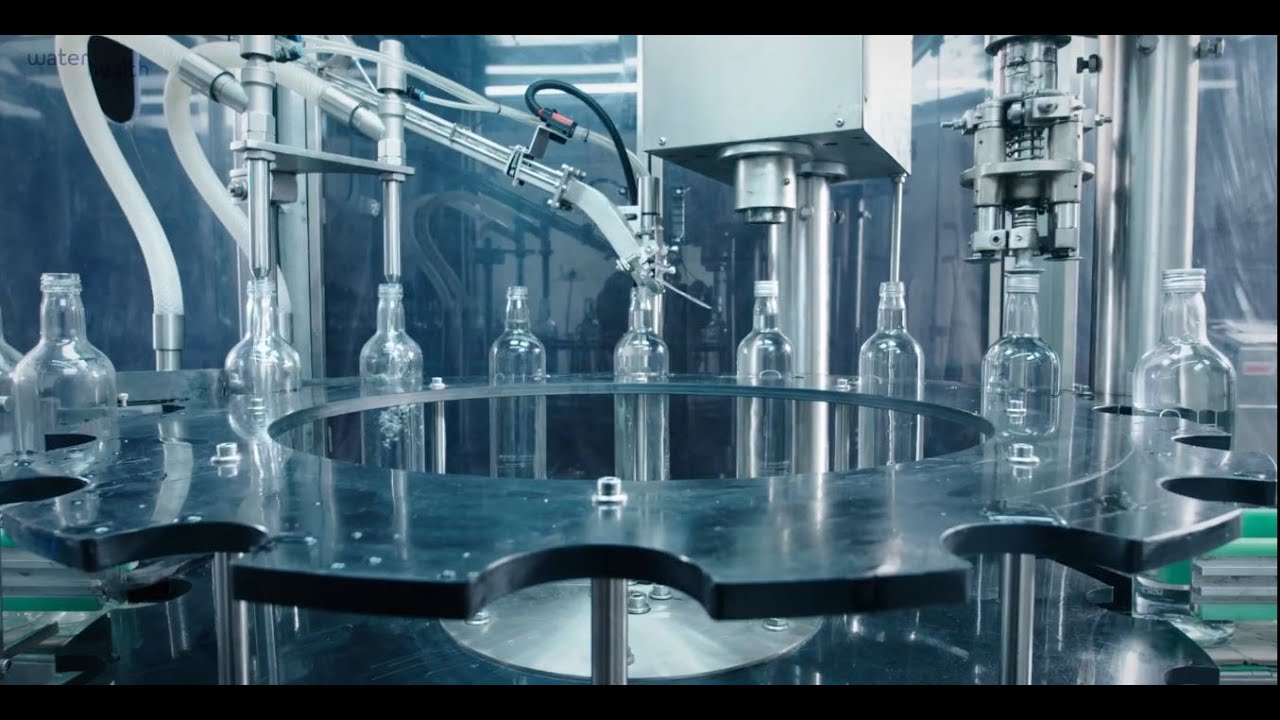

– Rotary Monoblock Glass Bottle Filling

– Linear Washing Filling For Glass Bottle

– Linear Washing capping For Glass Bottle

– Filling for Mineral Water

– Capping for Mineral Water

– Rinsing For Juice

– Hot-Filling For Juice

– Capping For Juice

– Rinsing for Carbonated Soft Drinks

– Filling for Carbonated Soft Drinks

– Capping for Carbonated Soft Drinks

– Rotary Monoblock Glass Bottle Filling

– Linear Washing Filling For Glass Bottle

– Linear Washing capping For Glass Bottle