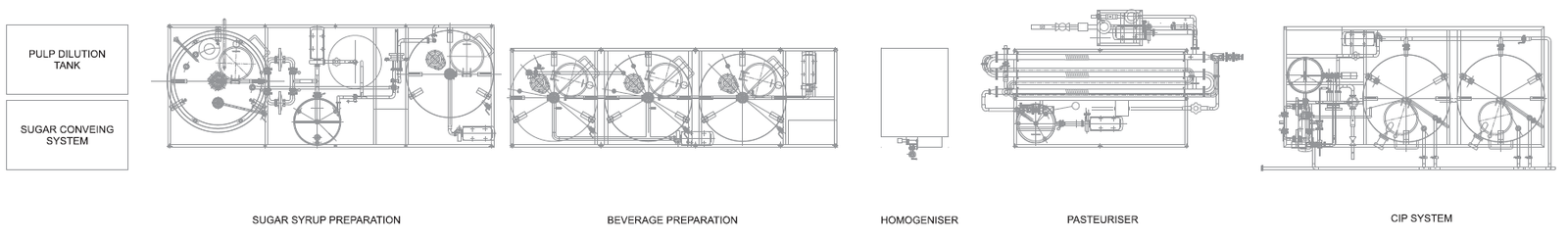

SUGAR SYRUP PREPARATION SECTION

To prepare the sugar syrup, we first dissolve sugar in heated water. We make the syrup to a 65 Brix concentration. After making the syrup, we filter it to remove any impurities and then cool it down. Once cooled, we transfer the syrup to the Ready Sugar Syrup storage tank. From this tank, we then transfer the syrup to the Blending tanks as needed.

In this section, we prepare the beverage by mixing water, flavor, sugar syrup, and additives. The flavor comes from the concentrate tank, the syrup from the Ready Sugar Syrup storage tank, and the water is transferred to the blending tank. In the blending tank, an agitator assembly—driven by a motor and gearbox—mixes the ingredients at a preset speed and time. After blending, the beverage moves to the carbonator for further processing.

CSD BLENDING SECTION

AUTOMATIC CIP SYSTEM

The system is mostly automatic, with some manual operations. For instance, the temperature of the CIP solution heating is controlled automatically, and the water level in the tank is maintained automatically. However, you will need to open the respective tank valves manually for both supply and return. Liquid flow diversion to the respective tanks happens automatically, but until the temperature reaches the desired level, the recirculation valve must remain open. Additionally, the operation timer will stop the pump as soon as the preset operation time is reached.

Product Category

Primary packaging

– Rinsing for Mineral Water

– Filling for Mineral Water

– Capping for Mineral Water

– Rinsing For Juice

– Hot-Filling For Juice

– Capping For Juice

– Rinsing for Carbonated Soft Drinks

– Filling for Carbonated Soft Drinks

– Capping for Carbonated Soft Drinks

– Rotary Monoblock Glass Bottle Filling

– Linear Washing Filling For Glass Bottle

– Linear Washing capping For Glass Bottle

– Filling for Mineral Water

– Capping for Mineral Water

– Rinsing For Juice

– Hot-Filling For Juice

– Capping For Juice

– Rinsing for Carbonated Soft Drinks

– Filling for Carbonated Soft Drinks

– Capping for Carbonated Soft Drinks

– Rotary Monoblock Glass Bottle Filling

– Linear Washing Filling For Glass Bottle

– Linear Washing capping For Glass Bottle