Fully automatic with integrated multiple work station for nitrogen purging, filling, capping & sealing used for filling metallic & plastic drums/containers from 120 to 250 liter range for end to end solution of filling & packaging for barrels/ drums/ containers etc. The model is designed for high filling production level featuring a high level of automation.

Accessories available

- Fume hood

- N2 Purging

- Bottom start filling

- Product pump speed Control as per filling speed

- Overflow Detection & alarm

- CIP cleaning system

- Interchangeable Lance

- De capping

- Filling

- Capping

- Automatic bung hole centering

- Pre N2 purging

- Post N2 purging

- Sealing

Can be configured for more flexible & automatic workstation

Salient Features

- Available in weight metric based or flow meter based filling based on product.

- Auto bung hole detection & servo based rotation for positioning.

- Automatic container moving by motorized roller conveyors.

- Can be equipped with deep diving type servo based nozzle which moves up gradually with filling.

- Options for Pre & post N2 purging.

- Quick setup & user friendly programming.

- Outside open-able nozzle with double seat to ensure maximum flow rate & accurate filling.

- Acrylic doors with safety locks provided.

- Can be compatible with flammable, hazardous, toxic chemicals which need to fill at high temperatures.

- Unlimited filling recipe generation & storage as per requirement.

- Specialized high temperature food grade silicone seals with tri-clamp based connection for easy cleaning.

- All the parts including the main valve, buffer tank, nozzles, Hose pipe, & pump are connected by tri-clamp for easy disassembling during the cleaning process.

- Compatible with online palletizer with multi product automation & conveyor system.

Technical Specifications

| Model | KM2H/L-Barrel Fill | KM4H/L-Barrel Fill |

|---|---|---|

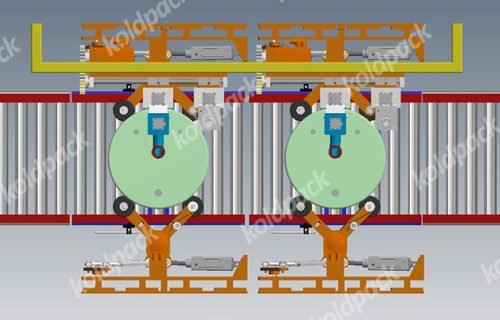

| No. Of Filling Head | 2 Head (Nozzle) | 4 Head (Nozzle) |

| No. of capping head | 1 Head | 2 Head |

| Output drum Per Hour | 55 to 60 Barrels per hour (200 Kg) | 100 to 120 Barrels per hour (200 Kg) |

| Filling Type | By Net weight/ flow meter based filling (Based on product) | By Net weight/ flow meter based filling (Based on product) |

| Nozzle System | Servo Based Deep Diving Nozzle(gradually up with filling) | Servo Based Deep Diving Nozzle(gradually up with filling) |

| Material Of construction | Contact parts : SS 316, Body Parts : SS 304Matt finish | |

| Electrical Supply | AC 440V Three Phase | |

| Compressed Air pressure | 4 to 6 Kg/ Cm2 | |

| Filling Range | 120 to 220 Liter barrels(Plastic/ HDPE/ MS barrels) | |

| Conveyer Type | PLC operated Motorized roller conveyer | |

| Application | Filling of Lubricant, Paint, Flammable chemicals, Solvent, Food product & other chemicals in 120 L container to 220 KG metal/ plastic barrels. | |

Operation

Koldpack automatic new weight filling machine is working on the principle of load call based weight filling suitable to fill liquid products in 10L buckets, 20L buckets & pails. The machine consists of inbuilt buffer tank with liquid level controller on ground level or up level for gravity based filling. Servo based chain conveyer system adjust the buckets in perfect position before starting the filling. This machine comes with automatic lid pressing device to make it more flexible. Examples of this type of filler for bulk products include all types of chemicals, lubricants, industrial solvent, paints, food products etc. High value products filled by these machines include specialty adhesives and paints, precious metals dissolved in acids, and other expensive specialty chemicals.